ATEX CO detection prevents worst case scenario

The ACOM CO detection system detected the formation of a glow nest at the spray nozzles of the drying tower and triggered the tower extinguishing system while the glow nest was still in the formation phase.

The spray tower – a large dryer for food – has an air flow of 80,000 m³/h. The picture shows caking on the injector nozzle, which has led to the formation of the glow nest.

Atex CO Detection switches off the drying tower at an early stage and thus prevents the development of a large-area spray dryer fire.

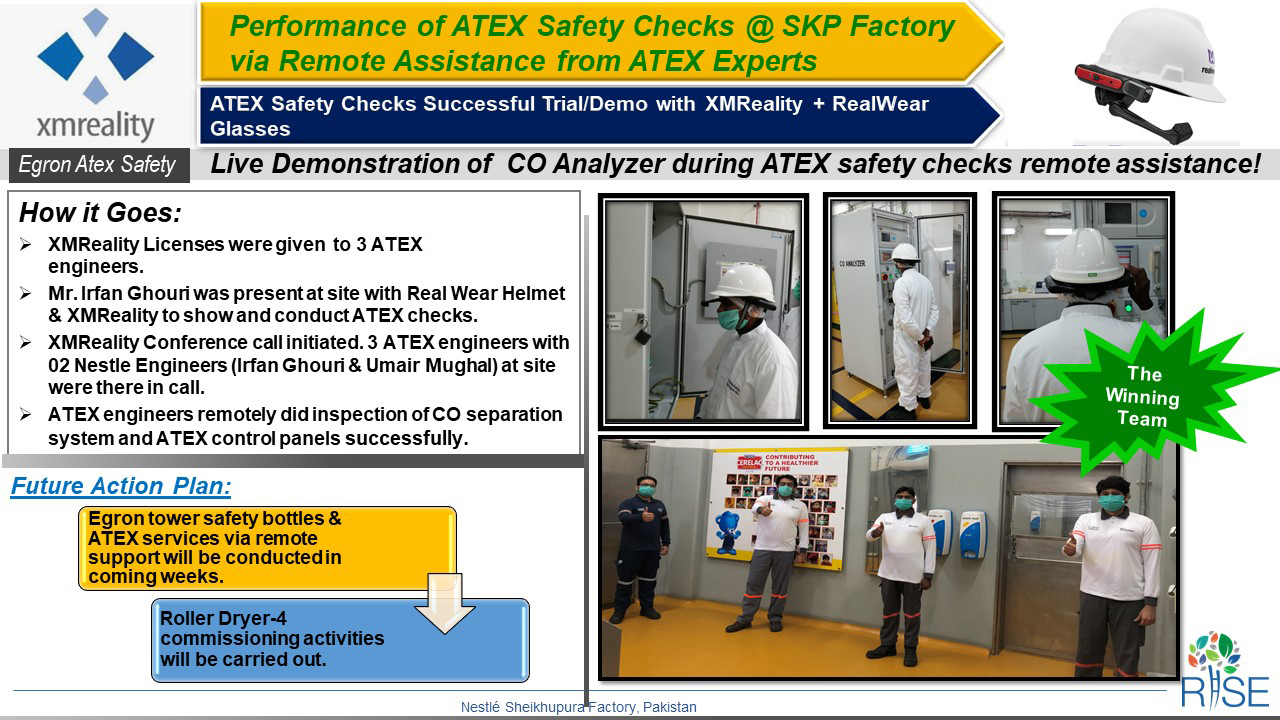

A successful remotely assisted maintenance…

We are very happy to receive such positive feedback from our customers in Pakistan. The remote assistance was provided by our service engineers to perform required safety checks on our CO detection system.

The successful execution of remotely assisted maintenance is really significant for us, specially these days where COVID-19 is far from over and the whole world is at halt. We also developed a remote assistance solution during the early corona days because we thought It would prove very useful in the upcoming days. ATEX was one of the early adopters of the remote assistance idea and knew its importance in advance.

Now six months forward, it feels great to see this solution working out just fine for our customers.

ATEX FloatValves: Developed in direct contact with our customers

Our mission to always offer the best possible solution is currently particularly evident in the example of our ATEX FloatValve explosion protection valves:

These have been tried and tested for years and are in use worldwide in sizes DN 100 – 600. For one of our customers, our largest DN 600 valve was not sufficient and one with a diameter of 800mm should be used if possible. A task that development engineer and product manager Markus Kille accepted and solved.

The valves are already in production. They will soon be tested and certified on our test field under real conditions.

Further information: Dipl. Ing. Markus Kille m.kille@atex100.com

Economic cooperation between Chinese and German SMEs

ATEX is a member of Sino-German Metal Eco City (MEC), a project of Zhongde Metal Group GmbH. It is an innovative industrial park, which will open up access to the Chinese market for German small and medium-sized enterprises (SMEs). The MEC is being developed on the outskirts of the city of Jieyang, in the eastern region of the southern Chinese province of Guangdong.

Zhongde Metal Group GmbH brings its experience and a comprehensive network of politics, science and business to the establishment of the “China SME Center”. The center offers German entrepreneurs direct access to a wide range of industries and innovative industrial parks throughout China. As an interface and meeting point for the Chinese economy in Germany, it is to develop into an important gateway to German medium-sized companies and its networks in cooperation with numerous partners. This is an initiative of Chinese Ministry of Industry and Information Technology (MIIT).

ATEX was being contacted and incorporated to take a lead and initiate projects for industrial and process safety in China starting from Guangdong province. ATEX expresses its greatest gratitude for being offered a membership by Chinese Ministry of Industry and Information Technology and to put their trust in us providing consultation and initiating projects. It will safeguard industries, masses and environment.

Industrial and academic exchange

As a part of TU Dortmund’s international cooperation agreement with Kyoto University in Japan, ATEX Explosionsschutz GmbH has long been partnered with TU Dortmund in order to facilitate the incoming exchange students. The purpose of this agreement is to strengthen the cooperation with foreign educational institutions and promote the academic exchange. This collaborative agreement focuses on a threefold mission:

- To promote collaborative research among academia, industries and the government.

- To support business start-ups by researchers or students and

- To manage and utilize the university’s intellectual properties.

Every year we host two exchange students from the department of Bio and Chemical Engineering, Kyoto University Japan. Exchange students are engaged in an ongoing product development process, where they are given the tasks which interest them the most or are most relevant to them. We work closely with them as they offer entirely different perspective on approaching the problem and what could be the possible outcome. In return they gain practical experience in a German working environment, possible applications of their field of study, existing problems in the industry and how solutions are developed.

Quick Quotation for OEMs

If you would like to have any vent panel related quotation, you can now use a separate section on our online shop. All you have to do is fill in the form with complete information. Filling out the form will only take about three minutes of your time. After you submit the information, we will send you the quotation as soon as possible. The reason we want to recommend this, is because it saves a lot of time as compare to the conventional process of going back and forth during the communication process. Through the quotation page, we will receive all the information needed to quote. It just removes the margin of error and minimizes the unnecessary communication.

Just make sure that you fill out the quotation page on the corresponding regional store. Here are the links to our regional stores:

For Europe click ATEX Explosionsschutz GmbH

For UK click ATEX Explosion Hazards Ltd.

For North America click ATEX Explosion Protection LLC

For Brazil click ATEX do Brasil Ltda.

For Asia click ATEX 爆発防護株式会社

For New Zealand & Australia ATEX Fire and Explosion Protection Ltd.

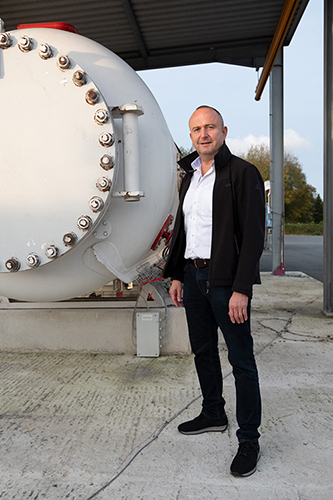

Test under real conditions

ATEX GmbH have a unique test field. On an area of over 5000 m2, explosion protection equipment is tested under real conditions. Pressure-resistant containers are available in various sizes for this purpose. The largest container has a volume of 140m3 and is designed for a pressure of PN10. The large area also offers the possibility to emulate complete production processes and is also used by plant engineers for testing purposes.

Special Services For Remote Assistance

ATEX Explosionsschutz GmbH has started offering a remote assistance solution through which we will be able to help our customers worldwide. Through this remote assistance service, we will be able to virtually see the on-sight problems via customers’ input in real time. Then instructions will be given accordingly to solve the problem. ATEX Explosionsschutz GmbH is completely prepared for such unusual circumstances the whole world is going through right now. There are worldwide travel restrictions, we might not be able to travel freely for many months to come but you can defiantly count on our remote assistance service if anything goes wrong. Contact us for more information: info@atex100.com.

Dr. Markus Roser on board

We are very pleased to welcome Dr. Markus Roser to Atex Explosionsschutz GmbH.

Dr. Markus Roser was previously Technical Coordinator of the research department “Explosion Protection” at the FSA. (Forschungsgesellschaft für angewandte Systemsicherheit und Arbeitsmedizin GmbH)

There he led large-scale explosion tests for the testing and certification of protective systems in accordance with ATEX manufacturer guidelines.

Dr. Roser is an active member of the working group for standardization within the “Technical Committee CEN/TC 305 ‘Explosive Atmospheres – Explosion Protection'” and has been dealing with the origin and course of dust and gas explosions for more than twenty years.

Dr. Markus Roser is taking over the function of Senior Key Account Manager at our company.

New Atex branch in Brazil

Explosion protection specialist Edmilson Pecosqui is your contact in our new office in Brazil.

His contact data:

ATEX do Brasil Ltda

Rua Domingos Capelato, 123

Valinhos – SP

Brazil

Tel +55 (11) 3929-6720